|

Deere Associates |

|

Although not clones or affiliates, I am including some of the more obscure tractors built in and around what is now the Quad Cities area in the teens and twenties. I had not planned to include the Dain, however, it has such an interesting and controversial history I decided to include it and its predecessors as locally built tractors. |

|

Copy write 2011, 2012, 2013 not for republication or sale without express written consent. All images are the property of their respective owners and are not to be reused without their express permission. |

|

In May 1860, John Deere’s 20-year-old daughter, Emma, married 30-year-old Stephen H. Velie, a Rock Island, Ill., businessman. Three years later, Velie joined the Deere family business, still a small local firm, and worked closely with his brother-in-law, Charles Deere, for the next 32 years. Deere & Co. was incorporated in 1868, with Velie as secretary and chief financial officer, a post he held until his death in 1895, by which time the firm had become a major farm equipment manufacturer.

Emma and Stephen had three sons, Stephen H. Jr., Charles and Willard L., all of whom were closely associated with Deere & Co. throughout their lives. Stephen Jr. worked for many years at the Kansas City branch, becoming manager in 1904, while Charles spent most of his long career at the Minneapolis branch. The youngest, Willard, worked for Deere from 1890 to 1900 before leaving to start Velie Carriage Co. The only Velie son to serve on the Deere & Co. board of directors, Willard was elected to that post after his father’s death in ’95 and stayed on the board for many years, resigning in 1921. Popular lore has it that Willard Velie saw his first automobile when Hi Henry’s Minstrel Show (it’s unclear whether the minstrels traveled by auto, an unlikely occurrence at the time, or used one in their act) came to town in May 1901, but he continued to build buggies and carriages until July 2, 1908, when Velie Motor Vehicle Co. was incorporated. His first car, the 1909 Model A, was well built and had a 4-cylinder, 30 hp engine.

The Velie was a success, with more than 500 cars sold the first year at $1,750 ($41,160 today) each. In 1910, Velie used a Lycoming engine, but started building his own power plants in 1911. In 1911, Velie began building a successful line of motor trucks. At about that time, the U.S. Army was exploring the possibility of using motor trucks to supply units in the field. The first test, which started Feb. 8, 1912, covered 1,509 miles from Washington, D.C., southwest to Atlanta, and then northwest across Tennessee and Kentucky to Fort Benjamin Harrison near Indianapolis.

Four trucks (White, Autocar, FWD and Sampson) made the initial run. The Sampson burned out its rod bearings after only 39 miles and was sent back, but the other three slogged on through the mud with many breakdowns, finally reaching Fort Benjamin Harrison on March 28.

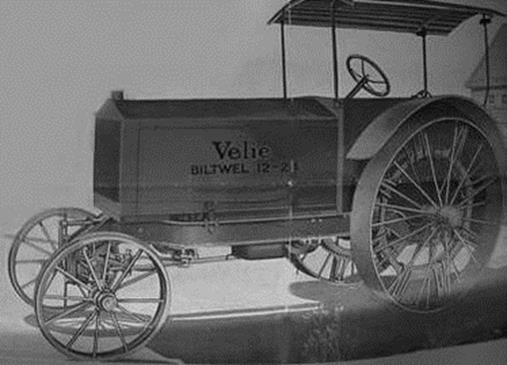

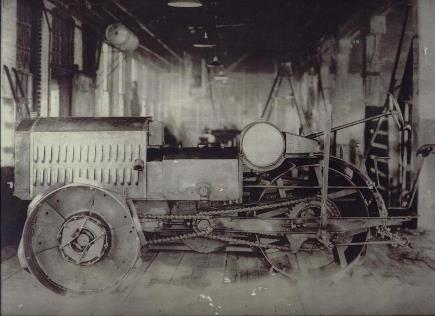

Velie merged his truck and car manufacturing concerns into Velie Motors Corp. in 1916 and began building a farm tractor. The Velie Biltwel 12-24 tractor reflected Velie’s expertise as an automobile and truck builder, being of lightweight design with a fully enclosed engine compartment, along with rounded, full rear fenders. Rated by the factory to pull three 14-inch plows (the tractor was usually demonstrated pulling a 3-bottom John Deere plow), the Biltwel had open drive gears and was powered by a Velie 4-cylinder, 4-1/8-by-5-1/2-inch bore and stroke engine with force-feed lubrication. Equipped with a canopy over the driver’s compartment, the 12-24 weighed 4,500 pounds and sold for $1,750.

For 1917, the Biltwel 12-24 was improved with enclosed drive gears and a more streamlined hood. The canopy was gone, but the tractor still cost $1,750, almost four times the price of a Fordson. Although the Biltwel 12-24 was well designed and a high quality machine, the price was just too high and in 1920, Velie exited the tractor business.

Strangely, despite having his own tractor line, Velie never seemed to make a push for the John Deere Company to buy or use his tractor line despite numerous confrontations with board president Butterworth. Velie was an outspoken proponent of having a tractor line and was a strong driver of the Dain all wheel drive and in January 1918, a letter from Velie to Butterworth was read into the board minutes in response to the decision to only produce 100 Dains. The result was the eventual agreement to purchase the Waterloo Boy Tractor line and works.

Velie continued to build his high quality cars, which starting in 1917 featured 6 cylinders. The 1925 Model 60 Royal Sedan was a sleek, closed body, five-passenger car with a prominent visor over the windshield. With a 118-inch wheelbase and 58 hp, the Royal sedan cost $1,635. In 1927, Velie made his son, Willard Jr., vice president and general manager of the company. The next year, a Model 88 with a 90 hp, 8-cylinder Lycoming engine and a 125-inch wheelbase joined the lineup.

Willard Velie Sr. died of an embolism on Oct. 24, 1928. The 1929 Velies were little changed from previous models and were the last offerings by the Velie Motor Corp., as Willard Velie Jr. died of a heart attack on March 20, 1929. In April 1937, Deere & Co. bought the idle Velie plant and machinery and finally closed the books on the firm in 1943.

|

|

Velie Biltwel |

|

Dain All Wheel Drive 12-24 |

|

The John Deere Dain All Wheel Drive tractor is one of those subjects the myths and legends have grown up around. Today, two Dains till exist (although Deere is loathe to admit the second one). The most famous one was restored by Frank Hansen and is now owned by Deere. The second one is now owned by the Sycamore IL Northern Illinois Steam Power Club where it leads the parade each year. This Dain has a long show history dating back into the 1950’s and 60’s and has a lower serial number than Hansen’s Dain. Parts of another Dain or two exist, and legends abound of a Dain graveyard where they were scrapped out after being recalled. March 5, 1912 Deere & Co Executive Committee resolution. “Resolved: That in view of the inevitable future use by the farmers for diverse purposes of gasoline and kerosene tractors, and especially since the trend is to use them in connection with implements, particularly plows, it seems vital to the interests of the Company that serious cognizance should be taken of the situation, and that through its experimental department, the personnel and talent of which shall be increased, if necessary, a movement to produce a tractor plow should be started at once having in view constantly, that the success of the same would be enhanced if not assured, were it possible to divorce the tractor from the plow and thus make it available for general purposes.” “I feel that we are making a great mistake if we do not take up the manufacture of the small tractor,” Vice President of Deere & Co Burton Peek wrote in a 1916 letter to William Butterworth, Deere & Co. president. “It has come to stay beyond any question, with so many of our leading competitors, plow manufacturers and others, making a tractor.” Deere had briefly sold Emerson Brantignham Big 4 tractors around 1910, but this was a partnership to sell Deere gang plows, not tractors. This reluctance was not shared by all the board members or the banks. In 1912 the board voted to pursue development of a tractor, a decision Butterworth was in very reluctant agreement to. Butterworth did not believe in or trust the tractor market, having seen many companies already go bankrupt on the new technology. However, board members such as Burton F. Peek, Willard Velie and George Mixter had convinced Butterworth and Deere & Co. would ultimately regret not gaining a share of such a growing market. The early 3-plow prototype based on the Hackney Autoplow by C.H. Melvin, and later Max Slovsky for Deere was abandoned in 1914, the go either direction, $6,000 proved unreliable. Joseph Dain, who was a company vice president, board member and head of the patent and experimental department, and former head of his own company and a respected inventor, began work on an what was called an “efficient, small-plow tractor” in 1914. “If it be possible to build a small tractor that will really stand up for five or more years’ work on the farm,” Mixter wrote Butterworth in 1915, “I believe they will be a permanent requirement of the American farmer and especially in view of the plow trade they carry with them, this possibility cannot be overlooked by Deere & Company.” By 1916, Dain completed three all-wheel-drive tractors to be field-tested: two with friction drive transmissions and one with a gear transmission. In field tests, the first tractor built pulled three 14-inch bottoms in clay sod at 2.5 mph. in the summer, it pulled two binders in heavy oats at 3 mph. A second tractor was sent to Winnebago, MN., where it pulled three 14-inch bottoms 6 inches deep at 2-1/2 mph. The third tractor – with the gear transmission – was completed too late to be tested with the others. In March 14, 1916, Dain sent the following telegram to Mixter from San Antonio, Texas: “Have followed tractor closely for two weeks. Conditions extremely hard and rough. Absolutely no weakness in construction. Gears, chains, universals, in fact all parts in good condition. Tractor has traveled nearly five hundred miles under extreme load. Change speed gear a wonder. I recommend to the board that we build ten machines at once.” Acting on Dain’s recommendation, Ten tractors were sent to Deere & Co. branch houses and were tested with positive results. C.C. Webber, a company vice president and director, wrote that “dealers could sell the (Dain) as a three-plow outfit for $1,500.” The testing was not without cost though. Dain, after spending a wet, cold week field-testing the tractor died of pneumonia on Halloween 1917. Dain’s tragic death, so near the completion of his project, did not have an immediate effect as on Nov. 19, 1917, Deere & Co ordered 100 Dain tractors to be manufactured at the East Moline, Ill., John Deere Harvester Works for sale in 1918. The price tag was $1,200 for the 12-24, 4 cylinder, 4,600-pound tractors. All eventually were sent to a dealership in Huron, S.D. For comparison the Fordson was listed at $750 Velie, who was in charge of overseeing the Dain’s tractor experiments, was furious. He accused the board of directors of bypassing his executive committee on important matters and resigned his chairman’s post of the executive committee. Velie wrote “We cannot profitably make as small a number as 100 tractors, [because] in the process [of doing so] we become the competitors of the independent tractor manufacturers wo have heretofore been our “allies”.. I cannot refrain from remarking that we should build tractors largely and whole heartedly, or dismiss the tractor matter as inconsequential and immaterial. The result was a split board in January 1918. The Dain was to expensive, and its lead engineer was dead. Director of Harvester works where the Dain was built W.R. Morgan, a recent hire from international Harvester stressed Henry Fords Fordson would redefine the tractor market. Deere’s retailers had been telling them if Deere did not have a tractor to bundle with Deere Implements, they would drop the Deere product line. It was known the Waterloo Gasoline Engine Company and its works and Waterloo Boy tractor were for sale, and so the decision was made to discontinue the Dain and purchase the Waterloo Boy. The Dain was ahead of its time, but was too complex and too costly. Not wanting to support the Dain, Deere recalled and destroyed nearly all of one of the most complex and innovative tractors of the time. The Sycamore Dain #34, Hansen’s #79 and parts of at least one other including the chassis survived. Legend has it that Deere recalled all the tractors, most located still in South Dakota and using dynamite destroyed each one recalled and pushed them either into a rive or lake. According to one person, during the WW2 scrap drives, his family’s lake was scoured and Dain parts were hauled out for scrap. Even after the Dain was long resigned to history, it has continued to cause controversy. Although the Sycamore Dain has hardly been a secret, and was used as a template for parts to restore his, Frank Hansen often claimed his was the only one. In 1983, Frank took Deere to court in Minnesota to force them to acknowledge the Dain as a John Deere as Deere for years insisted that the Model D was the first production John Deere model. The lawsuit was ultimately successful, forcing Deere to publicly acknowledge the tractor as the John Deere Dain. This didn’t stop the arguments on if the Dain was a true Deere, as at least one person has claimed it was painted different when Frank got it and Frank had photos of it with a different paint scheme. Individually, many Deere collectors also are reluctant to credit the Dain as an actual Deere, claiming it was a side project solely by Dain though this discounts the board actions and the John Deere serial tag, Due to family health issues, Frank eventually sold his Dain to Deere after unsuccessfully trying to sell it on Ebay for $1.6 million, where it has been on display in Moline and Springfield. Deere however, now claims the Hansen Dain is the only “Authentic” or “Complete” Dain on the rare occasion they will even acknowledge the existence of the Sycamore Dain only two hours from Moline as all parts on it are now Authentic JD parts. The Sycamore Dain however, has lost its original serial tag which was on it when it was donated to the club by the Williams family who had showed it at the Geneseo AE&TA show in the 1960’s until moving to California. The Geneseo club at the time lacked the facilities to store the Dain, so the family offered it to the Sycamore club in 1974, wanting it to remain in Illinois.

|

|

Above: The “Melvin” prototype Below: The Sklovsky prototype

|

|

Below: Sycamore Dain |

|

Below: The Dain |

|

< Return to List |